Condensation and Metal Roofing – Metal Roofing 101 with Todd Miller

Condensation and Metal Roofing

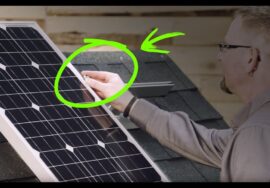

I was actually in this industry for quite a few years before I really understood condensation in a building and how a metal roof might impact it. In fact, I always sort of thought that metal roofs would regularly get condensation on the back side of the panels – between the metal roof panels and the roof deck. Turns out that is rarely if ever the case. Condensation occurs when the dewpoint is reached as warm moist area comes in contact with a cooler surface. That really doesn’t happen on the back side of metal roof panels because both are out in ambient conditions without any significant temperature or humidity differential. When it comes to condensation, the discussion is no different with metal roofing than it is with standard roofing. The place where condensation might occur is in the building’s attic. Fact is, we do all kinds of things to make our homes and other buildings tighter for energy efficiency purposes. We put in better windows and doors. We put house wraps or insulation on the outside of the home. The result is that the moisture we generate inside our homes from bathing, cooking, and etc. including even house plants and ventless gas stoves, now gets trapped inside the structure. That moisture migrates upward to the attic and, if it is not vented outward, it condenses on cool surfaces – usually the bottom side of the wood deck on the roof’s surface when it starts to cool down in the evenings. This really occurs no matter what sort of material is on the roof itself. The only exception is with a vertical seam roof that has direct contact with the roof deck. This could drop the roof deck temperature a couple of degrees from what it would be with, say, asphalt shingles. And that couple of degrees could be enough to be the straw that breaks the camel’s back and creates condensation that never occurred previous to the metal roof. A metal roof such as a metal shingle, though, that has an air gap between the metal and the roof deck, does not pose this risk. In addition to ventilation, vapor barriers and things like closed cell urethane foam can be very helpful at avoiding attic condensation.

Pardon my sandwich breath

Nice speech,, my shop condensate like rain in the winter. How do i fix it.

Robert McCully – what are the layers of your structure from inside to outside on both the walls and roof? What ventilation methods do you use? Thanks!

The answer to your question depends a lot upon the exact construction of your building.

Feel free to email me photos and description: todd@asktoddmiller.com

Generally speaking, though, things like dehumidification, vapor barriers, insulation, and ventilation can all play roles.

There are also products like DripStop that may be helpful.

I just replaced a 16’ sheet of metal on a roof less then 2 years old for a “leak” that was caused by sweating. It decking boards used for nailers under it (so it had air flow) and the attic had 2 gable vents. Yet when I pulled the sheet it was soaked on the bottom side as were the shingles under it! I live in northern Kentucky and the humidity here is pretty high I grant but don’t tell me they won’t sweat they will every time! The metal heats and cools faster then the air around it and causes sweating! I’ve seen buildings rain on the inside with no water standing on them at all!

This guy is flat out wrong….

I don’t think people understand condensation and how airflow promotes it. We have a metal roofs on several identical open structures with no walls in upstate New York. They are adhered to 2×4 purlins. During cold, especially foggy, the backside of these sheds are soaked, with water dripping off them. This has nothing to do with air temp differential on either side of a roof, the metal panels themselves change temperature a different rates than air temp and sometimes they promote condensation. The one in a field is worse than the same structure next to the house and under a tree. This says that when condensation conditions occur, more airflow allows more water to accumulate as air blowing by drops it moisture. This is why my shed in the protected space gets less condensation. Panels adhered to solid decking condense less, not because ambient air above and blow the panel is the same, but because there is less ambient airflow hitting the panels limited only to the amount between the deck and raised ridges. There is just less water available to condense. In fact, I think it is a mistake to encourage ambient airflow under the panels- such as putting metal on battens when going over existing roofing to “vent the roof”. On the contrary you want to insert foam at the even edges to prevent airflow.

I agree in a heated home with a cold attic, it makes sense to vent the soffits and roof ridge to get house moisture out. You need a vapor barrier to prevent attic air from touching the back of the metal. In this case you still don’t want ambient air reaching the back of the panels either. For solid decking synthetic underlayment plus plywood is probably enough, along with sealing the metal ridges at the eaves. For open air framing (purlins) manufactures are adding felt to absorb condensation, but this is not great. They should be designing panels with adhered layer of closed cell foam underneath that lays flat and is offset so metal ridges overlap and insulation mates correctly. This would eliminate condensation all together in all situations.

I have a steel building in Florida and it sweats water like crazy. Temperature differential is most definitely an issue.

Nice explanation.