How to: Install Corrugated Iron COLORBOND® or ZINCALUME® Roofing

#corrugatediron #metalroofing #colorbond

Our roof plumber Darren shows you how he installs corrugated COLORBOND sheet metal. The original Australian corrugated roof sheeting and wall cladding is ideal for modern and traditional architecture in residential and commercial applications.

A lightweight yet strong roofing and walling material

Versatile – Can be laid flat or sprung curved

Nominal cover width: 762mm

Minimum roof slope: 5°

The following information is included in this video:

* Installing the sisalation foil underneath the roofing sheets

* Which fasteners are used when installing the roof sheets

* Cutting the width of the sheets to fit the width of the building

* Why use the corrugated iron on a pitch roof

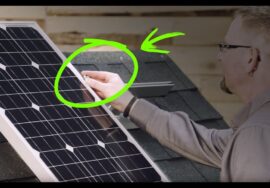

* Turn the top of the roof sheets up to stop wind driven rain

Finish the sides off using barge cappings:

See our range of Colorbond Corrugated Iron and more roofing products here:

See our range of Zincalume Corrugated Iron and more roofing products here:

sen a few roofing videos now why is the lining always sagging?

Thanks for an excellent video – the tip about turning up the ends with pliars was one I’d not thought of and is gunna save me a squillion in silicone sealant! Cheers – Simon / Adelaide

Simon Trangmar glad we could help!

Great video. I have to put this on my workshop. Are the sides watertight as they are and what do you do on the top where you turned up the corrugation?

The sides are made water tight using a barge capping on the sides. This is the video: https://youtu.be/v28-8Rwm0bE

Doesn’t condensation drip off the underside of the metal, onto the saggy vapor barrier, and then run down into the house???

I agree. Surely the condensation pools in the drapped material. What is the membrane you have used?

Very informative, great job Sean.

Thanks Sunstate roofing services. Happy roofing ??

I’m starting to think that maybe Hugh is just a stage name, and his real name is Aiden.

Think you are onto him!

When screwing in the sheets, how do you avoid hitting the nails/screws that join the battens and rafters?

Screw the battens in top and bottom, knowing the roofing screw is going through the middle.

Just how to use j hook in metal roofing

Thanks for the message. This is difficult to avoid, when you find you hit a nail or screw you need to slightly angle the roofing screw.

Killing it Bois ???

Would have made about 5 bucks on that one. ???

Aaron Campbell ????

Get the staple hammer like the chippies. Soooooo much easier. Thanks me later.

Thanks for the tip. ?

The irony is that the screw pattern you’ve used there is probably more intense, or at least equal to, most corrugated roofing I’ve seen installed in Japan – typhoon capital! If you saw the level of construction here you would not be surprised at the level of storm damage either… That Queensland pattern is hardcore! Every rib on the top and bottom, and every second in between? What purlin spacing is this based on? Also, wouldn’t the screw depth affect this – like screwing a longer screw into 2×4 vs a shorter screw into 1×4? Actually a lot of the sheet metal roofing in Japan is just nailed on with capped screw shank nails… Good thing I can still watch Aussie DIY videos to learn how to do it right 😉 Cheers.

Caleb Fuller thanks for your feedback ??

What do Hollywood stars do when they are short on movie making, they go roofing!

Denis Danilov ?

Excellent guys

Ajith Rajapaksa thanks so much ?

Good vid.. what about cutting hips? Do you ever use a grinder or only snips? Thanks

Beautiful Bastard thanks. We either use our electric Excalibur’s or our tin snips. ?

Great video, very thorough and clear. Just wondering can you turn down the lower end of corrugated roof to avoid capillary action?

Thanks for the feedback. You can use pliers to turn down the lower part of the corrugated sheets. This will help, but corrugated does not work well on a flat roof compared to a profile like trimdek or klip lok and should not be used under 5 degree roof pitch.

Why did you bend roof top ridge

its to stop the wind blowing the rain up under thus causing a leak.

I didn’t get the point about using foil or not. When do I use it and when don’t I? Thanks nice video

Hi Matthew. I would recommend using foil when you have an enclosed space, like a garage, shed or house. And not using it when you have an open space like a veranda or carport. ?

Can you tell me what size screws you use predominantly in this video? I’ve seen the term NEO and EPDM, are they the same thing? Also are they multi-grip screws?

@MetalRoofingOnline Link isn’t working, it’s this one right? https://www.metalroofingonline.com.au/products/colorbond-roof-screws-12-x-50-multifix/

The roofing screws in this video: 12 x 50 multi fix (multi grip)

NEO and EPDM – the rubber seal on the screws.

https://www.metalroofingonline.com.au/roofing-fasteners/17-colorbond-roof-screws-12-x-50-multifix.html

I would use foil under all roofs in any situation no matter if its a closed building or not, when the moisture is on the underside due to cold mornings and the sun comes up it heats the iron which causes the roof to drip, with foil it does not, I have proven this myself as i have a variety of roofs with and without foil.

actorzone thanks for your feedback

Blowing dust/swarf from roofing metal sheets, wouldn’t that create a breathing hazard? This website recommends brooming carefully or hosing. https://build.com.au/swarf-and-corrosion

How about vacuuming with a HEPA filter?