Modified Bitumen Roofing Systems

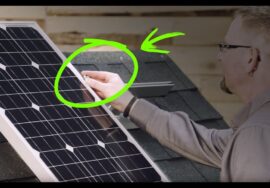

The presentation will examine the history of modified bitumen as well as their major features and benefits. The use of modified bitumen membranes in new, re-roofing and recover applications in both conventional and protected membrane assemblies will also be covered. The demonstration will show the installation of a modified bitumen roofing system from the deck up including the vapour retarder, the primary insulation and a cover-board application. The modified bitumen membrane will then be installed showing the base sheet and cap sheet, treatment of the edges and corners, and fastening and attachment techniques.

Hello, Were having a Bitumen 2-ply roofing system installed on our low slope home in Tampa, FL area. How important is it to have the initial layer nailed down underneath the self adhering layer? It makes sense to NOT administer the self adhering layer to the plywood. Is this primarily due to future repairs and for the long term future of the roof replacement?

I live in Scottsdale and was told to upgrade to this type of system. Total waste of money. What was once rubber type material is now shrivelled up cardboard. This system DOES not withstand the arizona heat. Hopefully you won’t have the same problem.

Where or what conference was this video filmed at?

If you live in Arizona, this system is total garbage. I paid more for this system and it could not withstand the Arizona heat. What was once rubber material, completely shriveled up into cardboard. I’m having to replace my whole outdoor balcony deck.

On the adhesive application, where is the can’t strip at the angles?

@The Roofer . . . Your information is incorrect. . Cant strip is required per soprema, gaf, manville, tremco and garland per their cold process specifications. Look it up

@Martin J Villasenor You are correct sir. Page 88 of the Soprema manual, “Install cants at all vertical roof transitions.” I’ve never done a cold ply process, always hot tar or torch welded. Should check before I open my mouth next time.

@Martin J Villasenor I only use it on systems where the engineer requires it. All BUR obviously have it and torch applied is done to specification according to blueprint/engineer. It’s been an approximately 80/20 split as far as not using it and using it in the last 20 years or so for me.

@The Roofer to my knowledge, the only modified system that does not require cant strips is a torch down system. But the thousands of squares of built-up and modified roofing that I have installed, have always required it.

@The Roofer and I’d course I am talking about spec installations (per the material manufacturers specifications)

substitute for insulator?

Help me understand WHY isn’t the Finish Surface be WHITE to assist in Sun reflection Plus reduction of Air Conditioning within Structure ?

It’s the arctic region version of roof color.

Just want I wanted to know. Hmm.

this mades no sense. The camera is all over the place.

Have a drink of RedBull while working.