Standing Seam Metal Roofing Vs Corrugated Screw Down Metal Roof – Big Differences between the Two

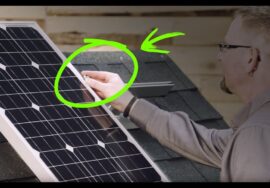

In this video we compare and contrast Standing Seam Metal Roofing vs corrugated or screw down metal roofing. We'll look Exposed screws used to install the corrugated metal and we'll show you how the fasteners are hidden in Standing seam by using a clip.

We talk about the seams in corrugated metal and how our standing seam metal is full length with no seams and how thermal expansion/ contraction affects the performance of metal roofing.

A large part of the success of any metal roofing project is choosing the right type of metal or profile for the specific application. The point of this video is to help you better understand the characteristics of standing seam and corrugated metal so can make a better informed choice as to which type of metal roofing is right for your next project.

Of all the things you want to hear, THE PRICE, he does not say a word about it.

We have a corrugated roof in the Upper Peninsula of Michigan. Heavy snow and ice loads. It’s 20 years old and in great shape. The screws are all holding up well.

We’re installing a standing seam roof on a construction project I’ve got here in the U.K – didn’t have a clue what this type of roof was until this video – very informative, thank you!

This is what the Director at the Canadian Roofing Association (CRCA) has to say about Hy-Grade: “I will say that I have researched this company – Hy-Grade Roofing – and did not take me long to find several complaints and bad reviews with the BBB (Better Business Bureau). These types of complaints would have been enough for me to pass on this contractor. I see many issues and complaints related to the many ‘Metal Roofing Companies’ who promise the world to the customer, then don’t follow through when it’s time to enforce the warranty or get issues rectified…” Not even the CRCA would use you as a contractor. I invite all potential customer to contact the CRCA before signing with Hy-grade!

So this is a standing seam commercial.

Agreed. Sounds like a standing seam distribution shill

yes. but still 50% correct information though

The standing seem roof also conforms to the shape of your roof even if you have underlayment. If you have just the slightest imperfection in the roof, it will show it. They call it oil canning.

Great video. I refer to it from time to time to get the most important information about standing seam roofs.

Straight to the point on 5 different categories…. I’ve looked thru many of video’s. Best way to let viewers know how to properly handle situations on metal roof panels and so on. Great video ????

When the roof is twice the amount of the cost of the entire shed….yikes

Oh hell, I’m almost half way done with my roof using corrugated metal.. expecting problems in 10 years I guess..

I always thought you get what you pay for. Not in this case! I went with Hy-Grade roofing even though they were by far the most expensive quote I received. Worst decision I could have made. They promised to install the roof in 4-6 weeks, of course they were late. When they finally showed up without the proper equipment and they damaged my property. They are really proud of the “Quality Audit” that they do, but of course they won’t give you a copy of the audit…lol BTW – the “Quality Audit” they did at my house consisted of 2 guys coming over to pickup the leftover junk they left at my house for a month. They never even went up on the roof! Horrible customer service experience! Save your money use someone else!

Just had Hy Grade Roofing install a metal roof at my house. Worst decision I could have made. They promised to install the roof in 4-6 weeks, of course they were late. When they finally showed up without the proper equipment and damaged my property. They are really proud of the “Quality Audit” that they do, but of course they won’t give you a copy of the audit…lol BTW -the “Quality Audit” they did at my house consisted of 2 guys coming over to pickup the leftover junk they left at my house for a month. They never even went up on the roof! Save your money use someone else!

Good video, but wow, you just kept talking circles on the expansion/contraction part.

If you put high temp membrane ice and water everywhere for corrugated metal to prevent to leak

I love my job I have doing roofing over 12 years now I love standing seams we r doing a 7500 square foot roof now

What wood you recommend going under that

What about price

Thirty two years ago I worked for a year in a sheet metal shop owned by Al a 70 year old man who grew up working in his family’s sheet metal shop. I didn’t do much installation but I did bend up a lot of single and double lock standing seam pans by hand useing an 10 foot break, in galvanized, copper, one lead coated copper job and hundreds and hundreds of attachment clips. I doubt I’ll ever have a copper standing seam roof on my own house but I will have a coated steel standing seam roof one day. Al sold me on standing seam when I was 18 for many of the same reasons laied out in this video being, no attachment penetrations and the ability to expand and contract.

Ps. When I asked Al how long a lead coated copper roof would last he said “the building will probably fall down before the roof ever fails”. It was a new concrete block building and this was its first roof.

you forgot to mention the PRICE difference.

all this praise on standing seam metal while working out of a building with typical metal building construction. nice.

I have been helping to install a standing seam floating roof system using a manual crimping tool, and automatic electric seam sealer. The panel are 46′ long, and the boss was unfamiliar with how to install this system, but he went ahead anyway after a brief description from the delivery guy. My sense was that you could either manual crimp at the beginning and at the end, and go over each seam with electric seam sealer, and repeat for each seam, or you could do assembly line process, and lay down all roof panels crimping each sheet manually 3 or 4 times, and then go over the whole roof with automatic seam sealer all in one step. I was also led to believe that you needed to use manual crimper at each clip fastener. My boss had a lot of trouble getting seam sealer to work properly. We began putting a fastener clip down every 2 feet which seems excessive to me. A clip at perimeters, and every 10′ would seem to be a better idea. It would be a lot less work, and I think using less clips more easily allows for expansion of metal, and much of what holds roof down is panels being crimped together. The boss is still trying to figure out what we have been doing wrong because the seam sealer is not doing the job.